Bring the fresh air in and keep the bugs out with an award-winning Bug Blocker door, designed to add security, ventilation, and pest control to your loading dock doors. We worked with food processors and tested at a USDA laboratory to develop our stainless steel screen for pest control. Choose from a variety of mesh sizes to keep out insects and animals of all sizes—even cicadas.

We’ve been around for 30 years and we will be here when you need us. Many of our original doors are still in use today.

The Bug Blocker® door retrofits with your existing door for a custom fit. Completely sealed for pest prevention along with OSHA compliant fall protection makes for happy inspectors and employees.

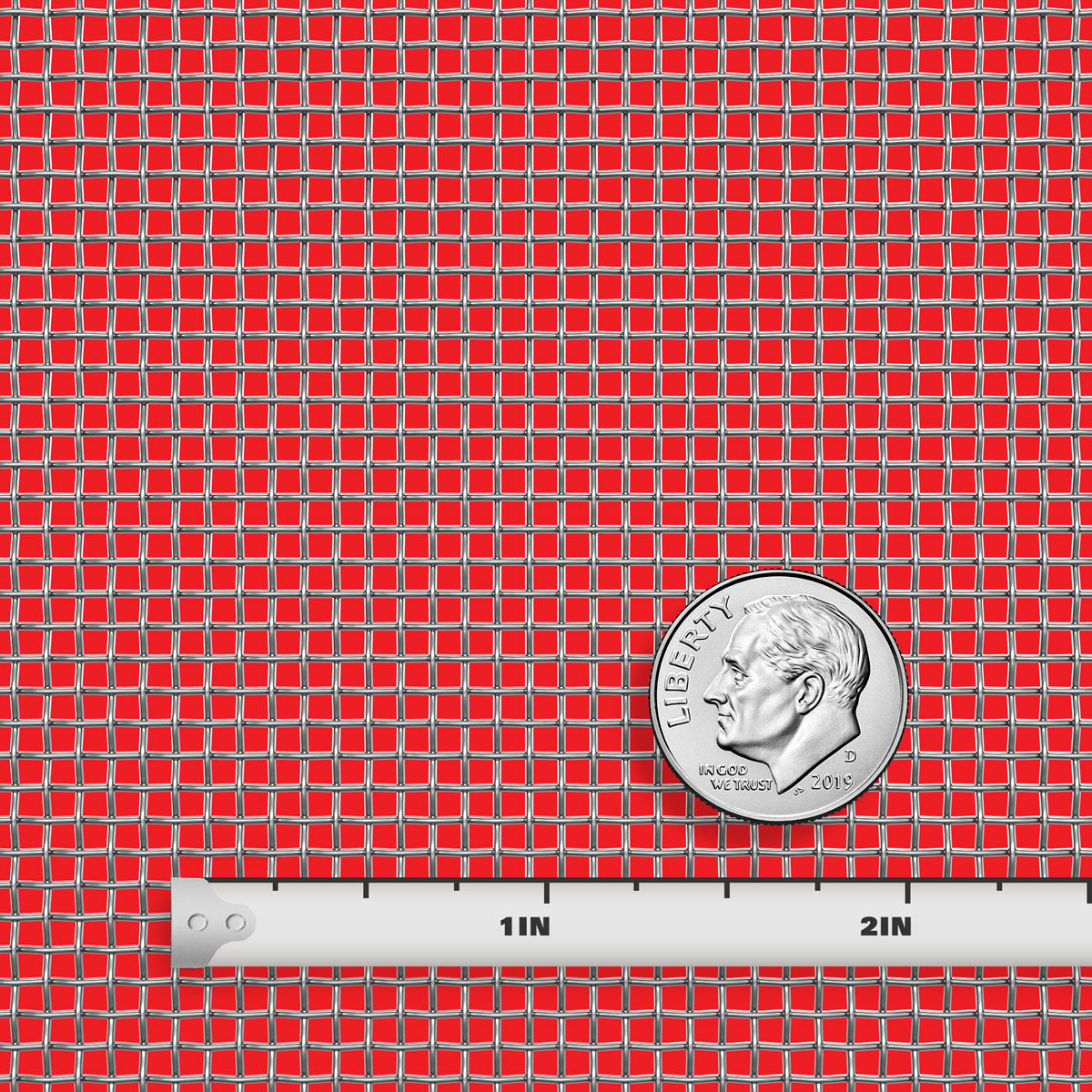

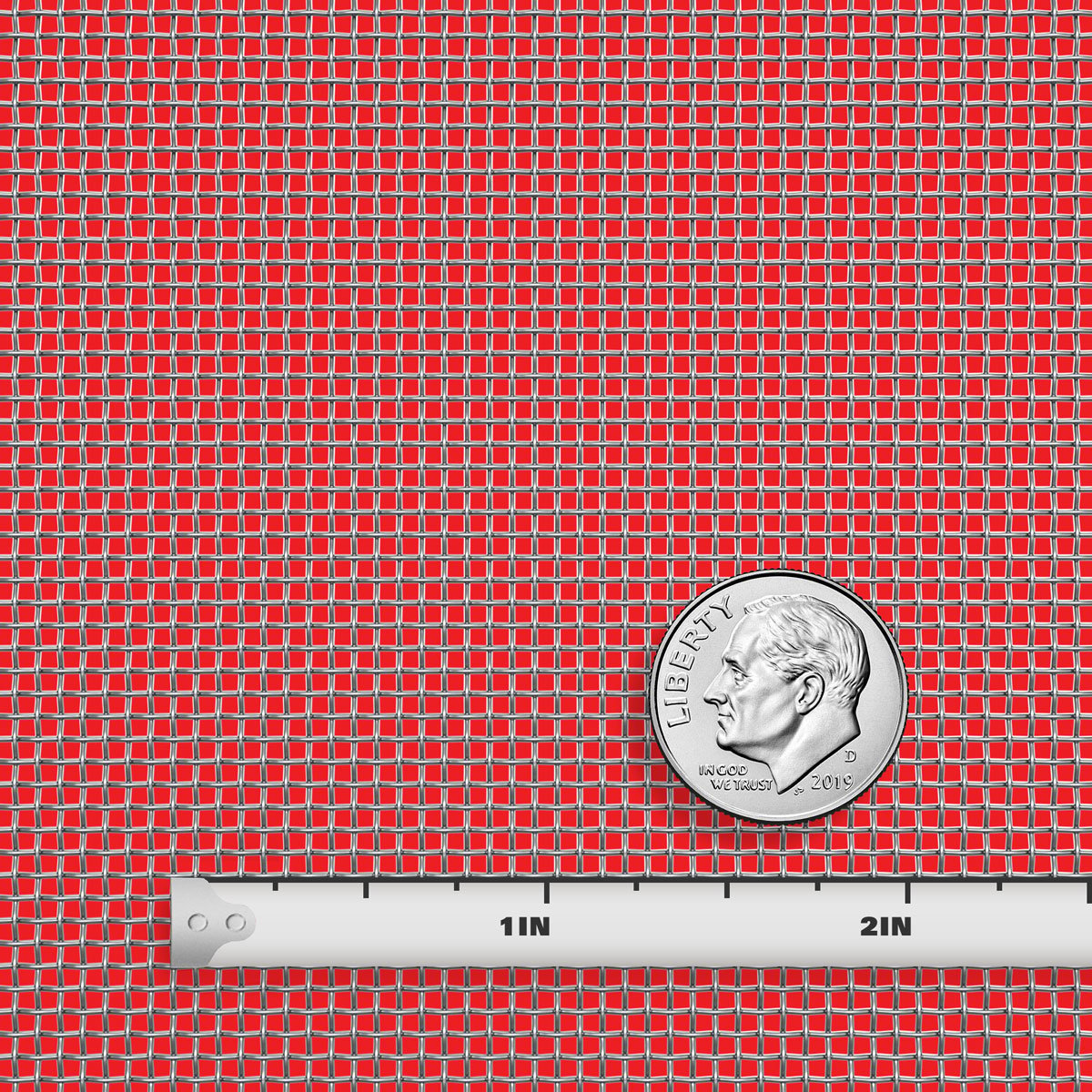

Our meshes meet the following industrial wire cloth standards:

304 Stainless Steel, Federal Spec. A-A-1037, ASTM Spec. E 437, ISO 9044

Add a second track for your screen door or choose our industry-leading switch track system for a seamless integration with your existing door

Industrial screen doors that keep your space well-ventilated without sacrificing security. Improve the wellbeing of your employees without increasing costs.

Choose from a variety of mesh sizes to keep out people, bugs, birds, and rodents. Designed to comply with industry regulations and keep your inventory secure.

Our steel doors provide security, fall-safe protection and inventory control while bringing fresh air in.

Meet OSHA requirements and help prevent loading dock injuries while increasing efficiency for your team with natural ventilation and light.

Stainless steel wire mesh that meets federal specification STD A-A-1037B. Our aluminum frames and commercial-grade hardware is custom developed for your doorway.

Helping you comply with Homeland Security, FSMA, AIB, HACCP, USDA, FDA, Food Defense, HARPC, OSHA, ISO and other quality, safety, and security programs.

Rasco doors are built from steel, the most recyclable product on the planet. Our doors safely keep pests out without resorting to harmful or expensive chemicals.

Founded in 1990 and family-owned, Rasco products stand the test of time. Each of our custom doors is given a serial number so obtaining replacement parts is hassle-free.

Rasco doors are designed and manufactured in owner and CEO Rosy Brown’s home state of Minnesota. Rasco is proudly WBENC Certified and Hispanic-owned.

All product and company names are trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.